Driving Innovation in Core Enterprise Sectors

Innovation is a continuous journey for businesses across all sectors, particularly within core enterprise areas like manufacturing, logistics, and operations. These foundational industries are undergoing significant transformations, driven by technological advancements and evolving market demands. Understanding how these sectors are adapting and implementing new strategies is crucial for sustained growth and competitiveness in the global economy, fostering resilience and forward momentum.

Core enterprise sectors are the backbone of global economies, encompassing a wide range of activities from raw material processing to product distribution. The pursuit of innovation in these areas is not merely an option but a necessity for survival and growth. Businesses are constantly seeking new ways to enhance their capabilities, streamline processes, and respond to dynamic market conditions. This drive for progress impacts everything from production methodologies to the overarching strategic direction of an organization.

How is Manufacturing and Production Evolving?

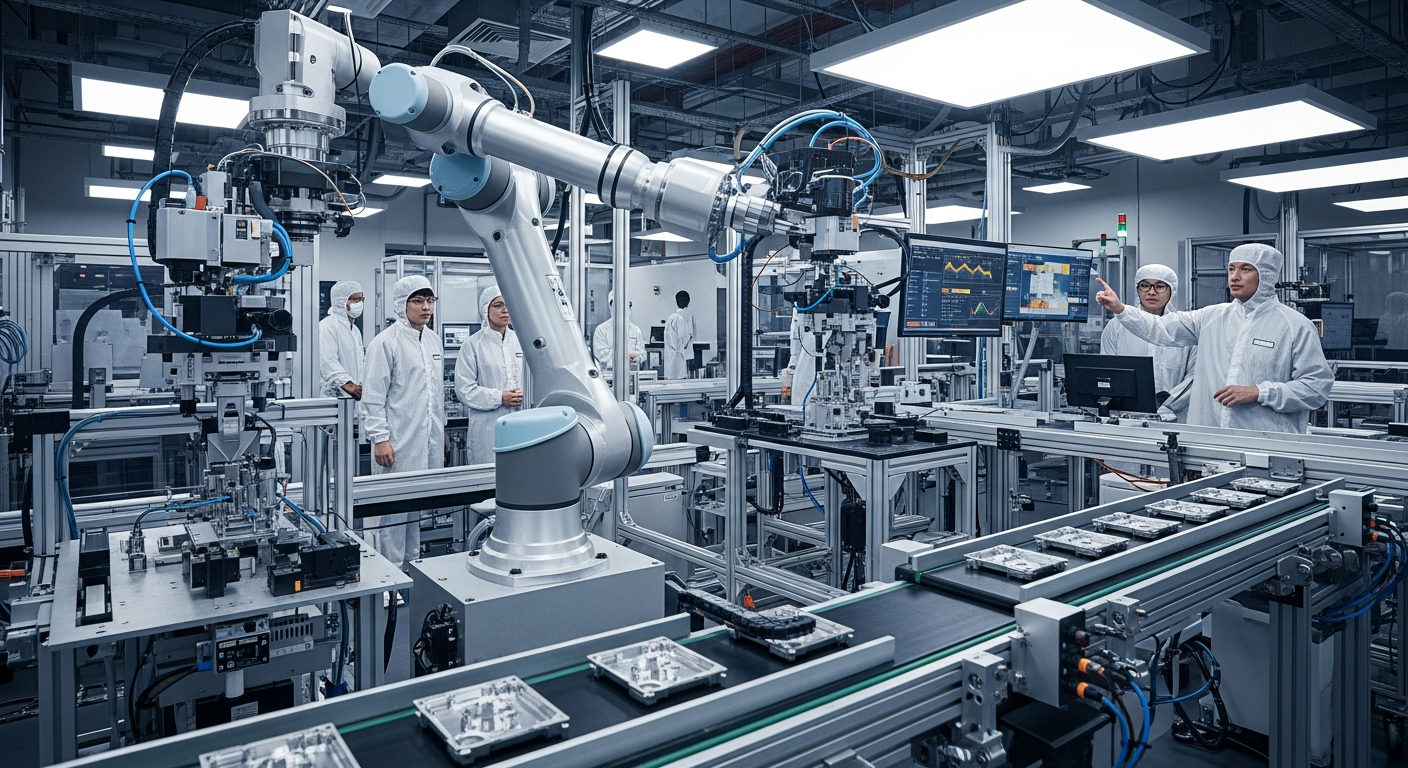

Manufacturing and production are experiencing a paradigm shift, moving towards more intelligent and interconnected systems. The integration of advanced technology, such as the Internet of Things (IoT) and artificial intelligence (AI), allows for predictive maintenance, real-time quality control, and highly customized production runs. This shift emphasizes flexible manufacturing processes that can quickly adapt to changing consumer preferences and supply chain disruptions. The goal is to create more resilient and responsive production environments that minimize waste and maximize output, fostering substantial efficiency gains.

This evolution also includes the adoption of advanced robotics and collaborative robots (cobots) that work alongside human employees, enhancing precision and safety. Digital twins, virtual models of physical assets, are being utilized to simulate and optimize production lines before physical implementation, significantly reducing development time and costs. These innovations are redefining the capabilities of manufacturing and production, pushing the boundaries of what is achievable in terms of speed, quality, and customization.

Advancements in Logistics and Supply Chain Management

Logistics and supply chain management are critical components of enterprise operations, ensuring that goods move efficiently from point of origin to consumption. Recent innovations in this area focus on creating more transparent, agile, and robust supply networks. Blockchain technology, for instance, is being explored to enhance traceability and security across the supply chain, providing an immutable record of transactions and product movements. This increased visibility helps in identifying bottlenecks and ensuring ethical sourcing.

Furthermore, advanced analytics and machine learning are transforming how companies manage inventory, forecast demand, and optimize delivery routes. Predictive analytics can anticipate potential disruptions, such as weather events or geopolitical shifts, allowing businesses to proactively adjust their logistics strategies. The optimization of last-mile delivery through autonomous vehicles and drone technology is also gaining traction, promising faster and more cost-effective distribution for commercial enterprises.

Automation and Digitalization in Operations

Operations across various enterprise sectors are being revolutionized by automation and digitalization. Robotic Process Automation (RPA) is streamlining repetitive administrative tasks, freeing human employees to focus on more complex and strategic activities. This not only boosts efficiency but also reduces the likelihood of human error. Digital platforms are unifying disparate systems, enabling seamless data flow and enhanced collaboration across departments.

The implementation of enterprise resource planning (ERP) systems, combined with cloud computing, provides a centralized hub for managing various business processes, from finance to human resources. This holistic approach to workflow management allows for better resource allocation and decision-making. The ongoing digitalization effort aims to create smart factories and intelligent warehouses where nearly every aspect of operations is monitored, analyzed, and optimized in real-time, driving significant improvements in productivity and responsiveness.

Strategic Approaches for Enterprise Growth and Sustainability

For enterprises to achieve sustained growth, a forward-thinking strategy is essential. This involves not only adopting new technology but also fostering a culture of continuous improvement and adaptation. Companies are increasingly focusing on sustainability as a core strategic pillar, integrating environmentally friendly practices into their processes and supply chains. This includes reducing carbon footprints, minimizing waste, and utilizing renewable energy sources, which can also lead to long-term cost savings and enhanced brand reputation in the market.

Effective management of innovation involves encouraging experimentation, investing in research and development, and collaborating with external partners such as startups and academic institutions. Data-driven decision-making plays a crucial role in shaping future strategy, allowing businesses to identify emerging trends and capitalize on new opportunities. By prioritizing both technological advancement and responsible business practices, enterprises can secure a competitive edge and contribute positively to the global economic landscape.

In conclusion, the core enterprise sectors are undergoing a profound transformation driven by innovation and technology. From advanced manufacturing and production processes to optimized logistics and supply chain management, automation and digitalization are enhancing efficiency and shaping the future of operations. Strategic investments in these areas, coupled with a strong commitment to sustainability, are vital for growth and maintaining a competitive position in the global market. As enterprises continue to evolve, the integration of cutting-edge solutions will remain paramount for success.