Hydrophobic Coatings: The Invisible Shield Revolutionizing Car Care

The world of automotive maintenance has quietly undergone a remarkable transformation over the past decade. While enthusiasts debate the merits of traditional waxes versus ceramic coatings, a more fundamental innovation has emerged that changes how vehicles interact with their environment. Hydrophobic coatings represent a fascinating convergence of chemistry and automotive care, creating surfaces that actively repel water and contaminants rather than simply creating a barrier against them. This technology, once reserved for industrial applications and high-end vehicles, has become increasingly accessible to everyday drivers seeking longer-lasting protection and reduced maintenance. The science behind these coatings offers a glimpse into how nanotechnology is reshaping our relationship with vehicle maintenance, promising a future where cars might essentially clean themselves.

Understanding the Science of Hydrophobic Technology

Hydrophobic coatings operate on a principle that’s as fascinating as it is effective. The term “hydrophobic” literally means “water-fearing,” and these coatings create surfaces that repel water with remarkable efficiency. At the microscopic level, these coatings create a surface texture featuring countless tiny peaks and valleys that minimize the contact area between water and the treated surface. When water encounters this landscape, surface tension causes droplets to form spheres that roll off rather than spreading and adhering. The physics behind this is measured by what scientists call the contact angle—the angle formed between the surface and the edge of a water droplet. Traditional waxes might achieve contact angles of 90-100 degrees, while advanced hydrophobic coatings can reach angles exceeding 150 degrees, approaching what materials scientists consider superhydrophobic properties.

Modern automotive hydrophobic coatings typically utilize silicones, fluoropolymers, or more recently, silica-based compounds that create chemical bonds with the vehicle’s paint. Unlike traditional waxes that sit atop the clearcoat, these molecular-level bonds become part of the surface structure itself. This integration explains their remarkable durability—some professional-grade coatings can maintain water-repelling properties for years rather than months. The technology continues to evolve, with the latest formulations incorporating self-healing properties that realign molecular structures when activated by heat or sunlight, essentially repairing minor surface imperfections automatically.

The Evolution From Racing Technology to Consumer Application

The journey of hydrophobic coatings from specialized technology to consumer product reveals much about how racing innovations find their way to everyday vehicles. The earliest commercial applications emerged in the aerospace industry, where these coatings helped maintain visibility through aircraft windshields during rain. Formula 1 teams quickly recognized the potential benefits and began applying similar technology to their vehicles’ windshields and bodywork in the early 2000s. The advantages were immediate—improved visibility in wet conditions and reduced drag as water beaded and flew off rather than creating uneven surface friction.

What began as a competitive advantage on racetracks has undergone considerable refinement before reaching consumer markets. Early retail products offered modest performance and durability, often lasting only weeks before needing reapplication. Contemporary formulations have overcome these limitations through advanced polymer chemistry and application processes. The transition from professional to consumer markets accelerated around 2010 when several specialist manufacturers began offering simplified application systems that didn’t require professional equipment or training. Today’s market features everything from basic spray-on products that provide short-term protection to advanced multi-stage systems promising years of hydrophobic performance. This democratization of what was once elite technology has fundamentally changed consumer expectations about what constitutes proper vehicle protection.

Beyond Water Repellency: Hidden Benefits of Hydrophobic Protection

While the water-shedding properties of hydrophobic coatings provide the most visible demonstration of their effectiveness, their benefits extend well beyond keeping surfaces dry. Perhaps the most significant advantage is their ability to resist contamination from environmental pollutants. The same properties that cause water to bead and roll off also prevent many contaminants from bonding with the vehicle’s surface. Road salts, industrial fallout, tree sap, and bird droppings—all notorious for causing paint damage—have significantly reduced adhesion on treated surfaces. When contaminants do land on the vehicle, they’re more easily removed without the aggressive washing techniques that can introduce swirl marks and microscratches.

Hydrophobic coatings also offer substantial UV protection, helping to prevent the oxidation that leads to fading and dulling of automotive paint. This benefit is particularly valuable for vehicles stored outdoors or in regions with intense sunlight. The reduction in maintenance time represents another overlooked advantage—owners report significantly faster washing times as dirt and grime rinse away more easily. Some users even adopt a “waterless wash” approach for maintenance cleaning, using specialized products that lift contaminants while maintaining the hydrophobic layer. For fleet operators and car sharing services, this reduction in cleaning time translates to measurable operational savings, demonstrating how a seemingly cosmetic technology can deliver tangible economic benefits.

Application Challenges and Best Practices

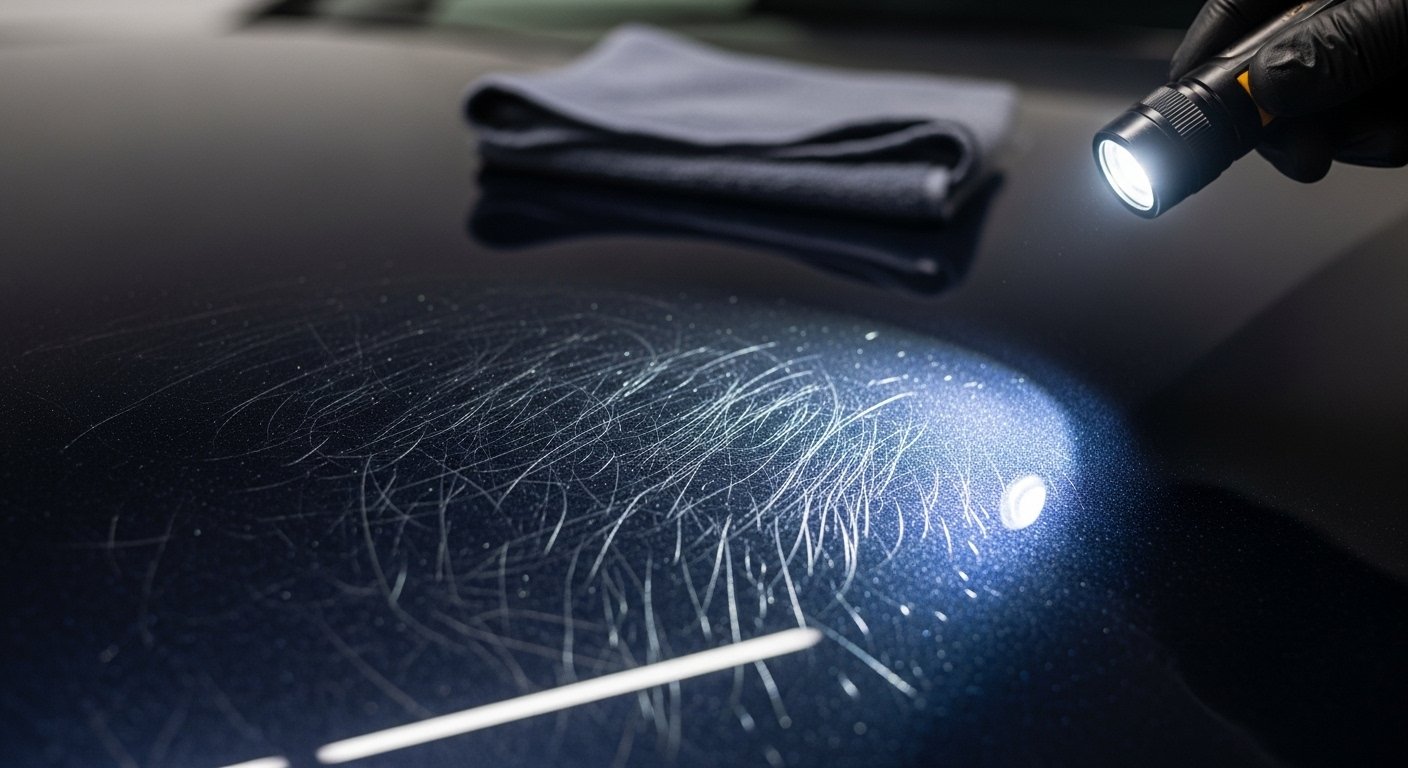

Despite their advantages, hydrophobic coatings present unique challenges that can intimidate even experienced detailers. Surface preparation remains the most critical factor in achieving optimal performance and longevity. Even microscopic contaminants trapped beneath these coatings can compromise their effectiveness and appearance. Professional application typically involves multi-stage decontamination processes, including clay bar treatment, chemical decontaminants for removing embedded iron particles, and often machine polishing to create a perfectly smooth substrate. The environment during application also matters significantly—temperature, humidity, and dust control all influence the final result.

Consumer-grade products have simplified this process considerably, but still require careful attention to detail. Application techniques vary dramatically between product types, with some requiring precise buffing times while others need specific curing conditions. The most common mistakes include applying products in direct sunlight, using excessive product, improper surface preparation, and impatience during the curing process. Environmental considerations have also emerged as manufacturers work to reduce volatile organic compounds in their formulations. The latest generation of products features water-based technologies that maintain performance while reducing environmental impact. For those committed to achieving professional results, investing in proper lighting equipment helps reveal high spots and uneven application before products fully cure—a critical step that separates amateur from professional results.

Future Directions: Self-Healing and Permanent Coatings

The horizon for hydrophobic coating technology suggests transformative developments that could fundamentally change our approach to vehicle maintenance. Research laboratories and specialized manufacturers are currently developing truly permanent coatings that chemically bond to automotive clearcoats at a molecular level. Unlike current offerings that eventually degrade and require reapplication, these emerging technologies aim to provide protection for the vehicle’s entire lifecycle. Early prototypes demonstrate promising durability in accelerated testing environments, withstanding thousands of wash cycles without significant degradation in performance.

Self-healing technology represents another frontier being actively explored. Current self-healing coatings typically require heat activation to repair minor scratches and swirls. Next-generation formulations aim to make this process entirely passive, with ongoing molecular rearrangement occurring at ambient temperatures. Some experimental coatings incorporate microcapsules containing repair agents that rupture when surfaces are damaged, automatically filling and healing imperfections. Perhaps most exciting are developments in photocatalytic hydrophobic coatings that use sunlight to break down organic matter on vehicle surfaces. These coatings essentially convert conventional pollutants into harmless byproducts that wash away with rain, pointing toward truly self-cleaning vehicles. While cost and application complexity currently limit these technologies to laboratory settings or specialized industrial applications, their eventual migration to consumer vehicles seems inevitable, promising a future where routine washing and detailing become optional rather than necessary maintenance activities.